Save Money by Becoming Socially Responsible

In recent years, emphasis sustainability has been a common trend in many industries. From eCommerce to industrial manufacturing, check out these ways you can make your packaging more environmentally friendly.

Sustainability doesn’t need to be expensive

Getting a product from manufacturer to consumer requires more packaging material than you’d think. There’s the main product packaging that the product reaches the consumer in. This can be anything from a bottle to a box. Then there is the packaging that the product gets shipped in. These are usually larger boxes that contain many individual products. But it doesn’t stop there. There is void fill material such as bubble wrap or sealed air to prevents damage or movement. Pallets and plastic wrap are included to ensure safe shipment. As you can see, that’s ALOT of material used to get a product to its end consumer. If you’re not careful this can impact both the environment and your spending negatively.

Pack Efficiently not Excessively

If you think your product is being over-packaged, consult a packaging engineer. They can help you protect your product in the most efficient manner so you aren’t using tons of extra material trying to keep it from breaking.

Often time’s people are using excess fillers and inserts, when they could save money and material by simply thinking outside the box (no pun intended). Packaging engineers come up with innovative designs that can save material while still keeping your product safe. If you don’t believe us, you can always get your package ISTA tested for certified approval.

Every one of us has received a package with way too much extra material stuffed in an oversized box. While, you may be appreciative that your product arrived safely, you were probably annoyed with the pounds of bubble wrap you have. The last thing you want is a customer to open your package and be annoyed.

More Boxes Less Material

A lot of people assume that buying standard one-size boxes will save them money because they order one order in bulk. However, the opposite can be true a lot of the time. By choosing a company that offers custom options you can order boxes that fit just right. If you try and use one box for too many products you could end up spending a fortune on shipping boxes that are half filled with air. Companies such as FedEx and UPS charge based on dimensional weight. This allows them to charge more for packages that are very light but have a large volume. In the end, it pays to be custom. You use fewer natural resources for your material and save money on shipping.

Reliable and Recyclable

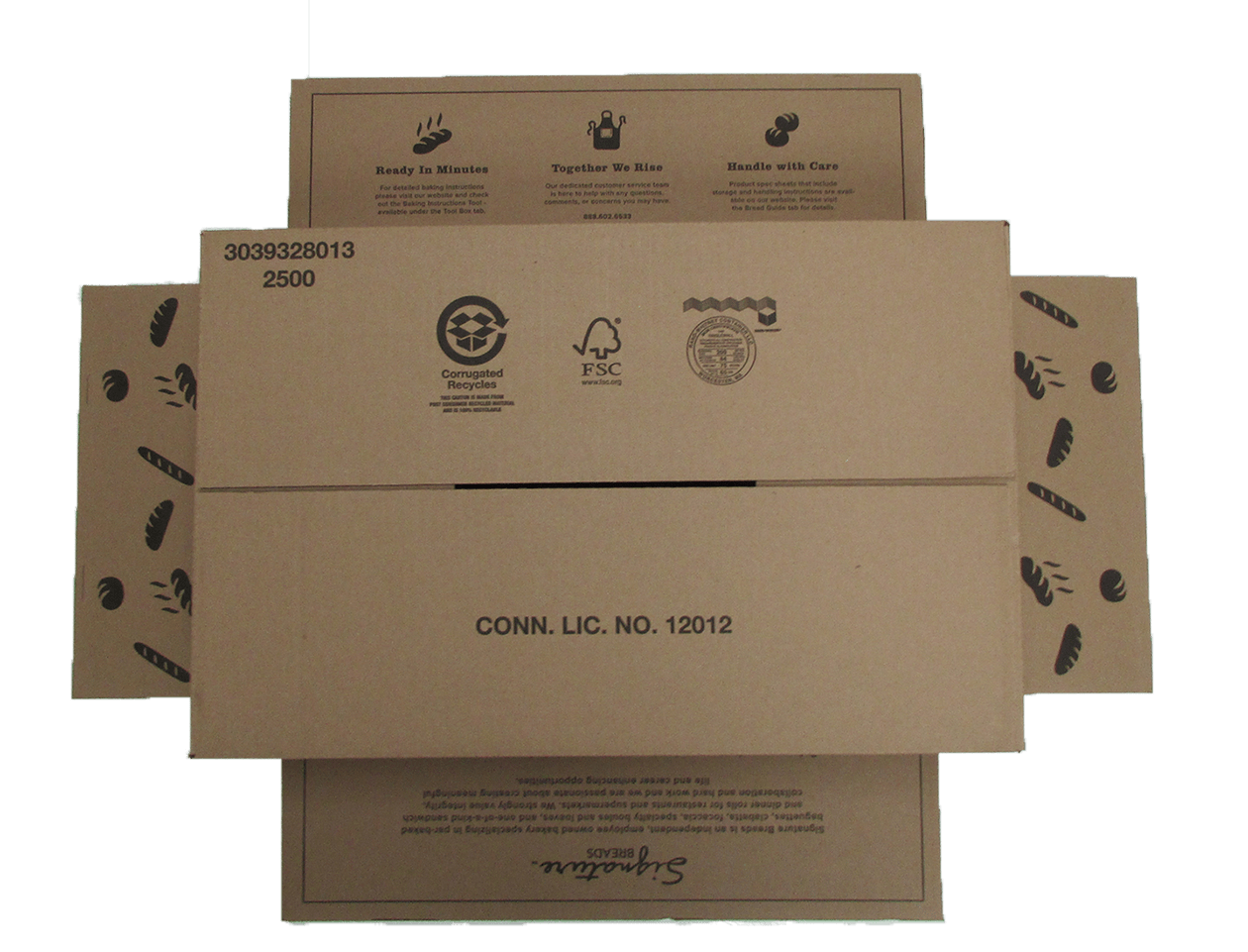

Corrugated is one of the most common forms of packaging you will see used today and that’s for good reason. It is lightweight and can still take the damage necessary to keep your product safe. It also happens to be one of the most recycled forms of packaging solutions used today. By choosing to purchase your packaging from a manufacturer that uses recycled material you are becoming a company that values sustainability. Non-virgin corrugated board is made from 70-90% recycled material. Not only does board made from recycled paper use 24% less energy in production but it will cost you less as well. Households all across the world recycle corrugated everyday. For every ton we recycle, we can save 9 cubic yards of landfill space.

Now more than ever people consider the environmental responsibility of the products they buy. You are speaking to your customer, telling them that you’re a responsible brand that cares for the environment. So really, you have nothing to lose and everything to gain!

Rand-Whitney can Help!

Rand-Whitney can help you save money and the environment. Our team of packaging engineers can look at ways to redesign your boxes to help you save money and improve your sustainability in the process. We also have an ISTA certified lab should you want to make sure your packaging can still hold up to wear and tear.