Mullen vs. ECT: Which test is right for you?

Is Your Box Strong Enough?

What kind of strength does your box need?

Mullen Test

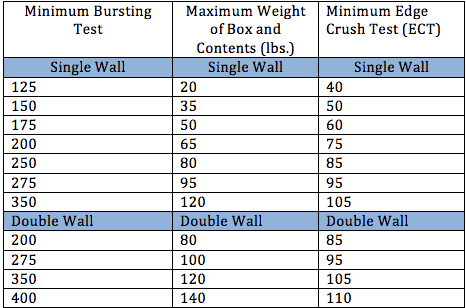

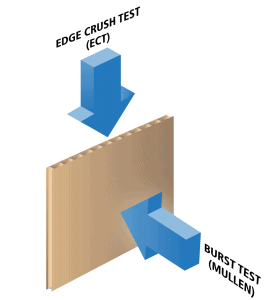

Mullen, or burst test is one of two industry standards for testing corrugated packaging. The Mullen test was the original test used throughout the industry. Mullen tests the liner-boards strength against bursting. This is ideal when you are packing products that would put pressure on small spots. The Mullen test shows how well a board can contain internal forces or withstand external forces. Mullen is used to simulate severe handling. In high speed sorting centers and distribution centers you can test to see if your package could survive the everyday wear and tear. The most common Mullen tested board is 200 pound.

Edge Crush Test

The ECT, or Edge Crush Test, has become more and more popular in recent years. This test looks at how the corrugated will hold up while being stacked. It tests top to bottom compression strength. This is advantageous because most boxes are stacked up for shipping and warehousing. The most common type of ECT sold is 32 ECT, which a lot of people look at as equivalent to 200 Mullen. This is because they have a very similar maximum suggested load. This is okay to assume in some situations, but it is important to remember that they do not test the same things. During an ECT test a small piece of corrugated material is compressed from top to bottom to see how much pressure it can withstand before buckling.

Older isn’t always better

ECT has grown into the most popular way to test corrugated strength because you can find a very similar strength board to its Mullen counterpart, but use less material in doing so. This is because Mullen has strict material guideline on how heavy each piece of material used in the construction must be. ECT is free to use different weights as long as they come together to achieve the right Strength. A 275-pound box may use 14.8% more material than its 44 ECT counterpart. Less material=Less money, which is very appealing to many customers when they don’t necessarily need one test or the other.

How to determine what you should use

To find out if you can save money on packaging, while maintaining its strength, ask one of our design engineers. Think to yourself “what does my package protect from and how is it used?” To defend against crushing, obviously the aptly named Edge Crush Test is the way to go. By using ECT instead of Mullen you may be able to get the exact strength you need without using as much material. Conversely if you are packaging a product that comes to a point or will put pressure on a small, focused area, you will want to use the Mullen test in order to gauge how the liner will hold up.

Want to make sure you are getting the most out of your packaging, give us a call at (800) 370-9111 or contact us here.